I love participating in a good alcohol-related event, especially as someone who designs and runs my own.

I love participating in a good alcohol-related event, especially as someone who designs and runs my own.

As a special treat to ourselves, J and I took a break from beer to explore Italian wines and vinting at a local wine-making and homebrew shop, Fermentations (disclosure: I occasionally work at the shop). Overall, the event was social, educational, hands on, and well thought out.

Here’s why it worked:

* The groups are small, only 4-6 couples. As a result, you can not only see everyone around the table, there’s an opportunity to talk with everyone over the course of the 2-hour tasting. Half of the people at our event were return customers.

* The hosts, Tim and Brenda, were knowledgeable about Italian grape varietals, the bottles they served, and wine making in general. They were even able to answer my more technical questions. It always feels like a great value when I can really learn something at an event like this. Talking points alone don’t cut it for me.

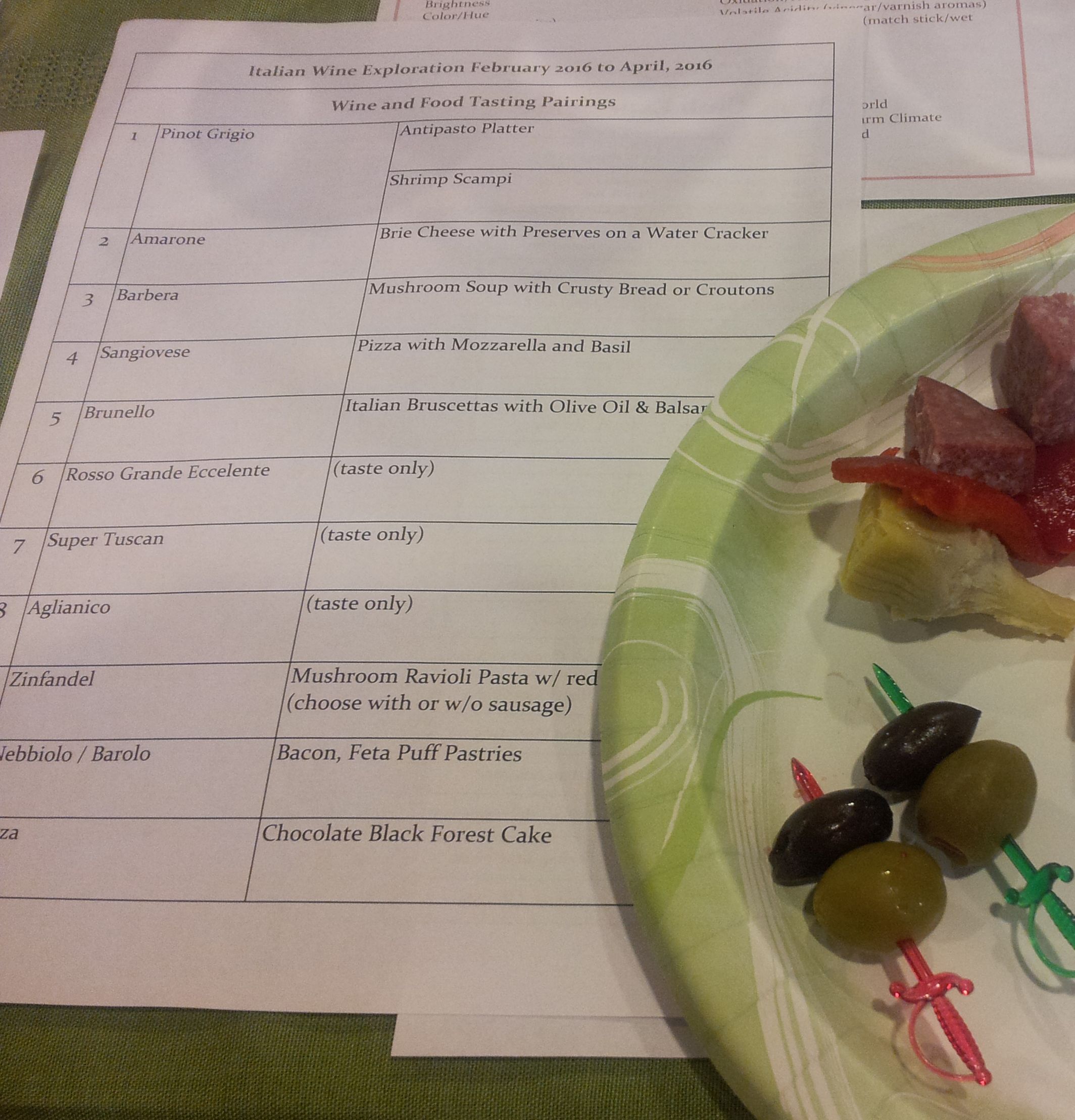

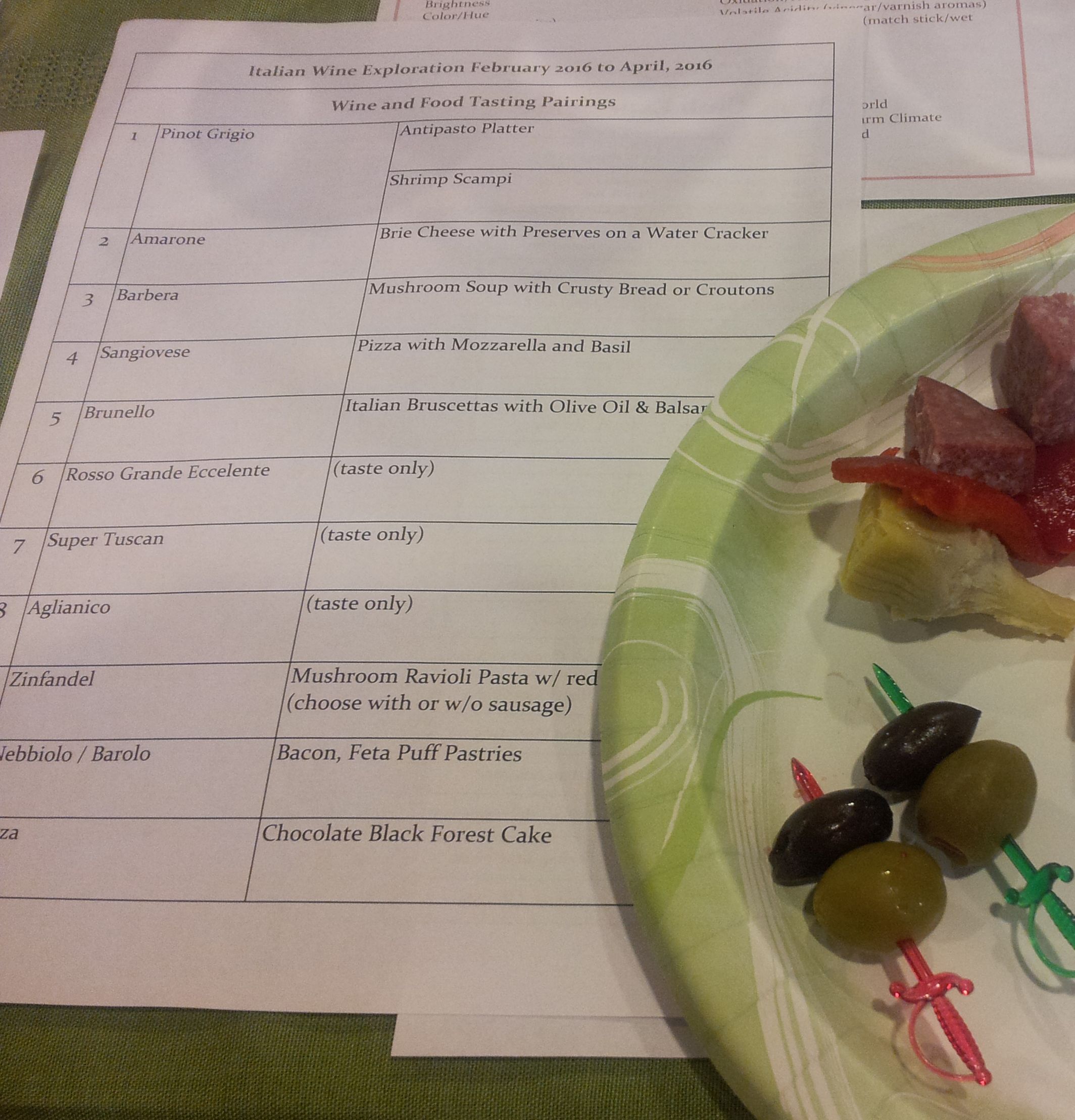

* Although each of these wine-experience events focuses on a region (in our case, Italy), the samples are diverse. We tried 11 different Italian wine styles, and a side-by-side tasting of commercial and homemade versions for 2 of them. Each wine was  chosen based on whether or not a similar wine-making kit was available. As a result, there were only 2 whites in this flight, but the reds varied in fruit character, body, and dryness. There was something for everyone’s taste.

chosen based on whether or not a similar wine-making kit was available. As a result, there were only 2 whites in this flight, but the reds varied in fruit character, body, and dryness. There was something for everyone’s taste.

* Nearly every wine was paired with food. Not only did this help to illustrate the wines’ versatility, it also helped keep us from over-indulging on empty stomachs. Smart.

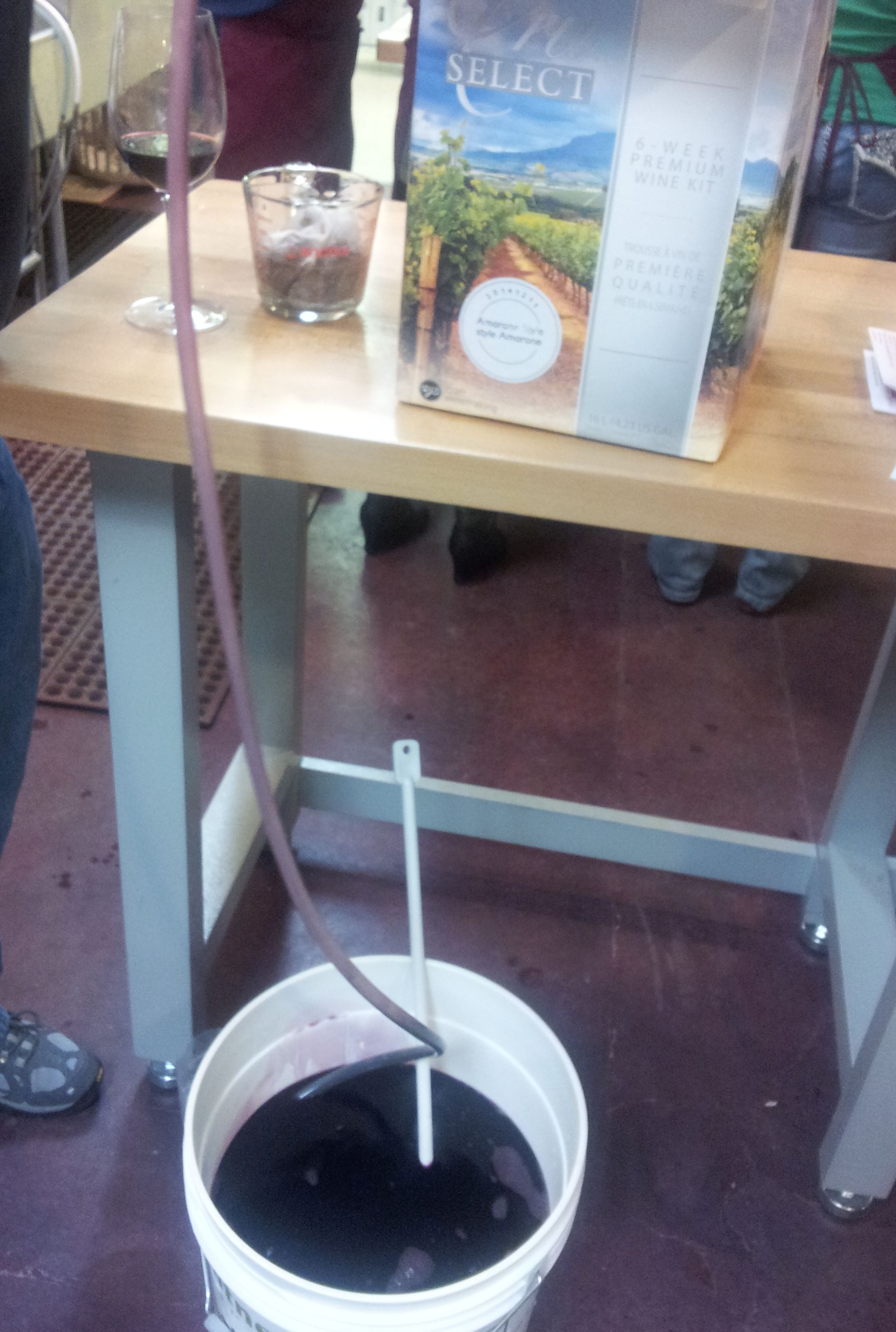

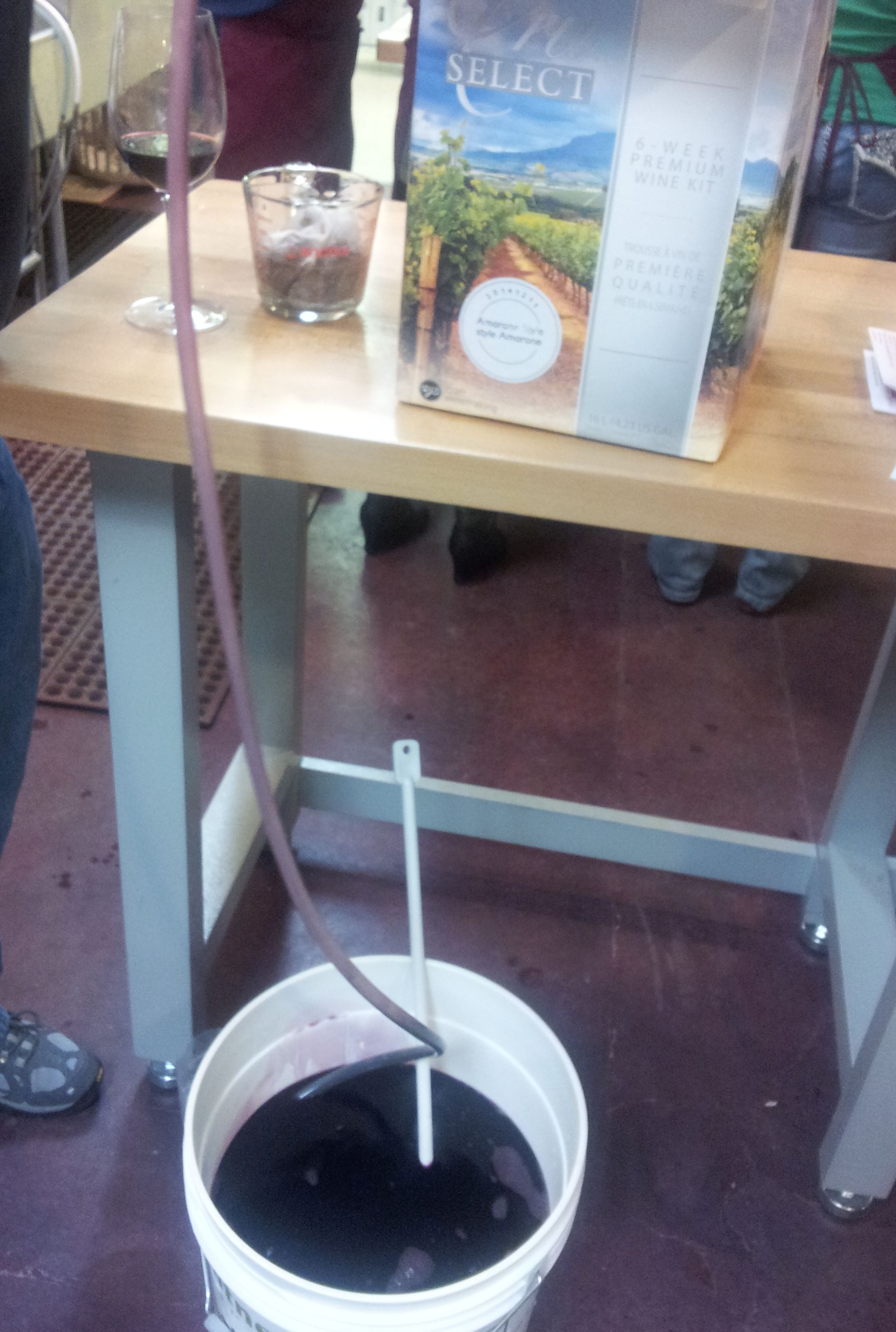

* Not just an excuse for drinking and eating, each couple got to choose a wine they wanted to make. J and I chose an amarone. As a brewer, I particularly appreciated this bit of hands-on experimenting to expand on what I learned from the tasting. As a bonus, we’ll trade wines with the other attendees on bottling day. We’ll bring home a nice mix of 5 different styles.

A good event benefits attendees in a variety of ways. Based on my experience as an event organizer, most customers are happiest when they not only have fun, but feel like they gained knowledge and experienced something unique. This event accomplished that. As a result, I’m likely to be one of the return customers at the table for the next event.